SLC 5/04 Processor

The SLC 5/04 Processor is a programmable logic controller (PLC) developed by Allen-Bradley, a brand under the Rockwell Automation umbrella. PLCs are industrial digital computers used to control various manufacturing processes and machinery in industrial settings. The SLC 5/04 is part of the SLC 500 series, which has been widely used in industrial automation since its introduction.

The SLC 5/04 is well known for its reliability and versatility in handling diverse automation applications. It plays a crucial role in monitoring and controlling processes in industries such as manufacturing, oil and gas, water treatment, and more. The name “SLC” stands for Small Logic Controller, emphasizing its compact design and suitability for applications where space is a critical factor.

Key Features:

The SLC 5/04 is equipped with various features that contribute to its effectiveness in industrial automation:

Modularity: The SLC 5/04 is modular, allowing users to customize the controller according to the specific needs of their application. This modularity is crucial for scalability and adaptability to evolving industrial requirements.

Communication Protocols: The SLC 5/04 supports multiple communication protocols, facilitating seamless integration with other devices and systems. Common protocols include RS-232, RS-485, Ethernet, and DH+ (Data Highway Plus).

Memory Capacity: The controller has a significant memory capacity, enabling the storage of complex programs and data. This is essential for handling intricate automation processes with precision.

High-Speed Processing: With its fast processor, the SLC 5/04 can execute logic and control tasks swiftly, ensuring real-time responsiven

critical industrial processes.

The programming of the SLC 5/04 Processor

Its typically done using ladder logic, a graphical programming language that represents control circuits through a series of graphical symbols. This programming method simplifies the creation of logic control routines.

Input/Output Modules: The SLC 5/04 accommodates a variety of input and output modules, allowing for connection to sensors, actuators, and other field devices. This flexibility in I/O options contributes to its suitability for diverse applications.

Applications:

The SLC 5/04 find applications across a broad spectrum of industries due to its reliability and versatility. Some common applications include:

Manufacturing: The SLC 5/04 is extensively used in manufacturing processes, where it can control machinery, regulate production lines, and monitor various parameters to ensure efficient and high-quality output.

Water Treatment: In water treatment plants, the SLC 5/04 can be employed to monitor and control processes such as chemical dosing, filtration, and flow regulation, contributing to the optimization of water treatment operations.

Building Automation: The SLC 5/04 can be applied in building automation systems to control heating, ventilation, air conditioning (HVAC), lighting, and security systems. Its flexibility allows it to adapt to the diverse needs of modern buildings.

The SLC 5/04 remains a stalwart in the realm of industrial automation, it offers a robust and flexible solution for diverse applications. Its modularity, communication capabilities, and high-speed processing make it a trusted choice for controlling and monitoring critical processes in various industries. As technology continues to advance, the SLC 5/04’s legacy persists, and its contributions to industrial automation are likely to be remembered in the context of the broader evolution of PLC technology.

Highlights

| Feature | Description |

|---|---|

| Processor | 16-bit processor running at 0.9 microseconds per Kilo-Instruction (KTI) |

| Memory Capacity | Typically 16K words for data and 16K words for program storage (expandable with memory modules) |

| Communication Interfaces | – RS-232 and RS-485 serial communication ports<br>- Ethernet communication via optional modules |

| I/O Modules | Supports a wide range of I/O modules including digital input/output, analog input/output, and specialty modules |

| Programming Language | Supports ladder logic programming language for easy implementation of control logic |

| Expansion Capabilities | Modular design allows for expansion with additional I/O modules, communication modules, and memory modules |

| Built-in Diagnostics and Troubleshooting | Provides extensive diagnostics features for easier maintenance and troubleshooting |

| Data Handling | – Supports integer, floating point, and binary data types<br>- Supports data manipulation and math functions |

| Redundancy Options | – Backup processor option for redundancy and fault tolerance<br>- Dual power supply option for redundancy |

| Compatibility | Compatible with various software tools for programming, monitoring, and troubleshooting |

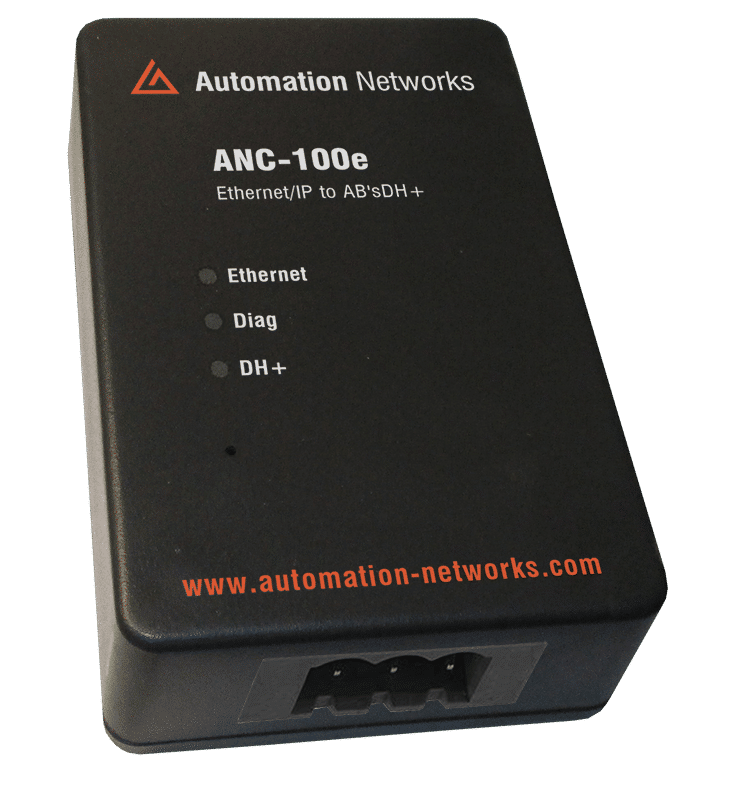

The ANC-100e DH+ converters provide communications between newer Ethernet Technologies and DH+ legacy PLC-5s and SLC/504s

The ANC-100e is a pocket-sized, high performance, Industrial Rated Ethernet DH+ Converter. Features include: Ease of Configuration via Web Interface and DH+ Auto Polarity Detection and DH+ Auto Baud Rate Detection.

$1,295 USD List.

20 min. theautomationblog review.

Data Highway Plus to Ethernet (S02)

In today’s episode of The Automation Show, I unbox and setup an ANC-100E Data Highway Plus to Ethernet bridge from Automation Networks. For more information about the show (and how you could win an ANC-100E) check out the “Show Notes” located below the video. The Automation Show, Episode 2 Show Notes: NOTE: Would you like your … Continue readingData Highway Plus to Ethernet (S02)

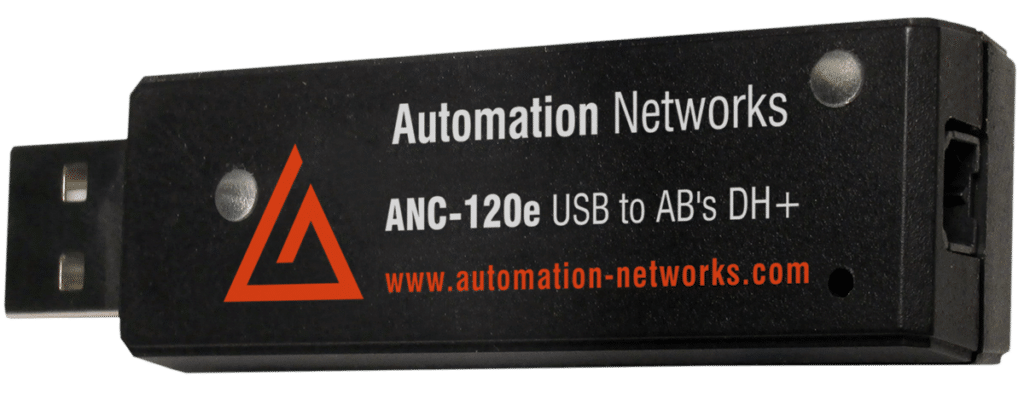

The ANC-120e is a competitive alternative to AB’s 1784-U2DHP PLC Programming Cable

Is an economical and high performance USB-to-Allen-Bradley Data Highway Plus converter interfacing major HMI, SCADA, PLC Programming packages to Devices on DH+. Its features significantly outperform AB’s 1784-U2DHP PLC Programming Cable operating at 12 Mg USB speed with the Controllogix Ethernet/IP Driver.

The ANC-120e works with all SCADA, MMI, PLC programming packages installed on your PC with USB direct access to the DH+ network and stations. These packages include RSLINX/LOGIX Classic & Enterprise with RSLOGIX 5/500, Wonderware DAServer & TCP/IO Server, Citect, and Kepware using Controllogix Ethernet/IP Drivers.

$1,295 USD List.

20 min. theautomationblog review

USB To Data Highway Plus (DHP, DH+) – Using the ANC-120e, a lower cost alternative to the 1784-U2DHP

ANC-100e Ethernet IP to AB's DH+ Converter

The Automation Networks ANC-100e communicates with all SCADA, HMI, PLC programming with direct Ethernet/IP access to the DH+ network and stations.

ANC-100e has similar replacement features as the Controllogix 1756-DHRIO / 1756-ENBT, and AB 1784 Interface Cards: 1784-U2DHP, 1784-KTx, 1784-PKTx, 1784-PCMK and Prosoft AN-X2-DHRIO Converters.

$1,295 USD List. Apr 1, 2024

ANC-120e USB to AB's DH+

The ANC-120e works with all SCADA, MMI, PLC programming packages installed on your PC with USB direct access to the DH+ network and stations. These packages include RSLINX/LOGIX Classic & Enterprise with RSLOGIX 5/500, Wonderware DAServer & TCP/IO Server, Citect, and Kepware using Controllogix Ethernet/IP Drivers.