Ignition HMI

Ignition HMI (Human-Machine Interface): Empowering Industrial Automation and Control

Introduction

In today’s highly automated industrial landscape, efficient monitoring and control of complex processes are paramount. Industrial facilities, whether in manufacturing, energy production, or utilities, rely on advanced technologies to optimize operations, ensure safety, and improve productivity. Ignition HMI (Human-Machine Interface) stands at the forefront of this technological evolution, providing a versatile and robust software platform that enables seamless communication between humans and machines. In this comprehensive exploration, we will delve into Ignition HMI, understanding its core functionalities, features, and significance in industrial automation.

Understanding Ignition HMI

Ignition HMI is an industrial automation software platform developed by Inductive Automation. It serves as a crucial bridge between human operators and the various machines, sensors, and control systems that constitute industrial processes. In essence, Ignition HMI allows users to create, manage, and visualize graphical interfaces that facilitate the monitoring and control of industrial operations.

Key Features and Capabilities

- Scalability: Ignition HMI is renowned for its scalability, accommodating both small-scale applications and large, complex industrial systems. Its flexibility makes it suitable for a wide range of industries, including manufacturing, energy, water treatment, and more.

- Web-Based Access: One of Ignition HMI’s standout features is its web-based architecture. Users can access and control industrial processes from virtually any device with a web browser. This remote accessibility is invaluable for real-time monitoring and control, even from off-site locations.

- Data Visualization: Ignition HMI excels in data visualization, allowing users to create highly customizable dashboards, charts, and graphs. These visuals display real-time data from sensors, Programmable Logic Controllers (PLCs), and other industrial equipment, making complex data more digestible for operators.

- Historical Data Logging: The platform offers robust historical data logging capabilities. This feature allows users to record and store historical data, facilitating trend analysis, performance evaluation, and informed decision-making.

- Security: Security is paramount in industrial settings, and Ignition HMI addresses this concern comprehensively. It incorporates various security measures to safeguard critical systems and data, protecting against unauthorized access and potential cyber threats.

- Scripting and Customization: Ignition HMI provides users with the ability to implement custom logic and functionality through scripting and customization options. This adaptability ensures that the platform can be tailored to specific industrial needs and workflows.

- Integration: Integration is a hallmark of Ignition HMI. It can seamlessly integrate with a diverse range of industrial devices, databases, and third-party systems. This versatility enables users to build comprehensive automation solutions that leverage existing infrastructure.

- Cross-Platform Compatibility: Ignition HMI is compatible with multiple operating systems, including Windows, Linux, and macOS, further enhancing its accessibility and versatility.

The Role of Ignition HMI in Industrial Automation

Now that we’ve explored Ignition HMI’s core features, let’s dive deeper into its role within industrial automation.

1. Real-Time Monitoring and Control

Ignition HMI empowers operators with real-time insights into industrial processes. Through intuitive and customizable graphical interfaces, operators can monitor critical parameters, observe equipment status, and make immediate adjustments when necessary. This real-time visibility enables proactive decision-making, minimizing downtime and optimizing efficiency.

2. Data Visualization and Analysis

Effective data visualization is a cornerstone of Ignition HMI. It transforms raw data into comprehensible visuals, such as charts, graphs, and trend analysis. This graphical representation aids in identifying patterns, anomalies, and performance trends, allowing operators and engineers to optimize processes and troubleshoot issues efficiently.

3. Historical Data and Reporting

Historical data logging is pivotal for post-process analysis and regulatory compliance. Ignition HMI stores extensive historical data, which can be retrieved and used for generating reports, compliance documentation, and performance analysis. This historical perspective aids in long-term process optimization and adherence to industry standards.

4. Remote Access and Mobility

The web-based nature of Ignition HMI offers the advantage of remote access. Authorized personnel can monitor and control industrial processes from virtually anywhere, using devices ranging from computers to smartphones and tablets. This capability is particularly valuable for addressing urgent situations and reducing the need for physical presence on-site.

5. Enhanced Security

In the era of cybersecurity threats, Ignition HMI prioritizes security. Its robust security measures include user authentication, role-based access control, encryption, and audit trails. These safeguards protect against unauthorized access, data breaches, and potential cyberattacks, ensuring the integrity of industrial operations.

6. Customization and Adaptability

Industrial processes vary widely across different sectors and even within the same industry. Ignition HMI’s scripting and customization options empower users to tailor the software to their specific needs. Whether it’s creating custom algorithms, integrating unique hardware, or designing specialized dashboards, the platform can be adapted to accommodate diverse requirements.

7. Integration with Existing Systems

Ignition HMI excels in integration capabilities. It can seamlessly connect with various industrial devices, including sensors, PLCs, SCADA (Supervisory Control and Data Acquisition) systems, and databases. This integration streamlines data exchange, allowing for a holistic view of operations and fostering interoperability with legacy systems.

Applications Across Industries

Ignition HMI’s versatility extends across a wide spectrum of industries:

- Manufacturing: In manufacturing, Ignition HMI aids in optimizing production lines, monitoring equipment health, and ensuring product quality. It facilitates data-driven decision-making, leading to increased efficiency and reduced downtime.

- Energy and Utilities: In the energy sector, Ignition HMI plays a crucial role in managing power generation, distribution, and monitoring of critical infrastructure. It enables operators to respond swiftly to grid fluctuations, ensuring uninterrupted power supply.

- Water Treatment: Water treatment plants rely on Ignition HMI for monitoring and controlling the purification process. Real-time data visualization helps maintain water quality standards, while historical data supports compliance reporting.

- Oil and Gas: In the oil and gas industry, Ignition HMI is used for remote monitoring of drilling operations, pipelines, and refineries. It enhances safety, minimizes risks, and optimizes production.

- Pharmaceuticals: Pharmaceutical manufacturers leverage Ignition HMI to maintain stringent quality control and adherence to regulatory standards. Real-time monitoring ensures consistency and product safety.

- Food and Beverage: In the food and beverage industry, Ignition HMI helps ensure product quality, compliance with food safety regulations, and efficient production processes.

Ignition HMI stands as a testament to the power of modern industrial automation software. With its scalability, web-based accessibility, data visualization capabilities, historical data logging, security features, customization options, and seamless integration, it plays a pivotal role in optimizing industrial operations across a multitude of sectors.

In an era of ever-increasing automation and data-driven decision-making, Ignition HMI empowers organizations to not only monitor and control industrial processes effectively but also to adapt and thrive in dynamic environments. Its role in enhancing efficiency, reducing downtime, ensuring compliance, and improving safety cannot be overstated.

As industries continue to evolve and adopt cutting-edge technologies, Ignition HMI remains at the forefront of the industrial automation revolution, poised to drive innovation, increase productivity, and shape the future of industrial processes for years to come.

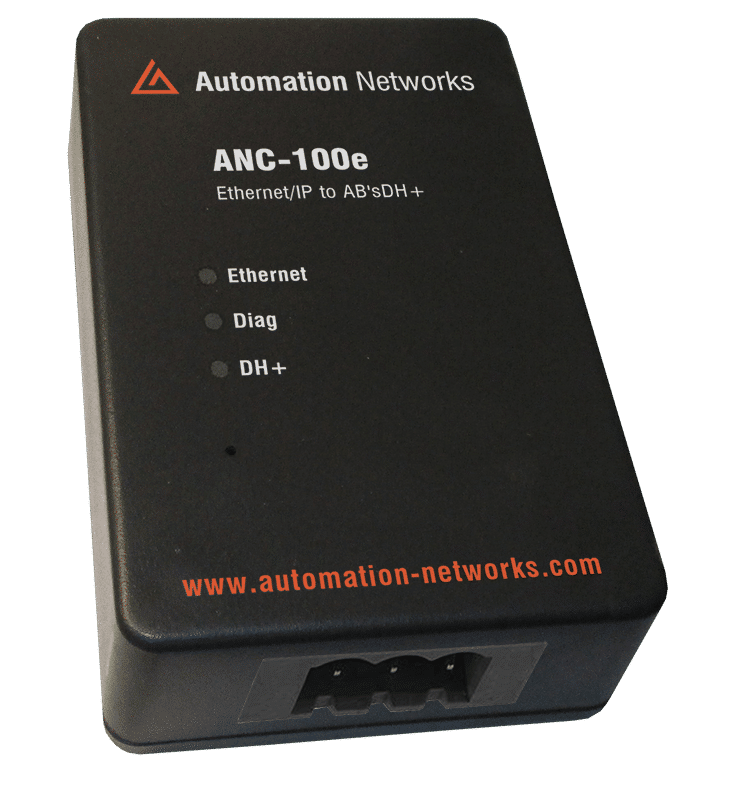

The ANC-100e DH+ converters provide communications between newer Ethernet Technologies and DH+ legacy PLC-5s and SLC/504s

The ANC-100e is a pocket-sized, high performance, Industrial Rated Ethernet DH+ Converter. Features include: Ease of Configuration via Web Interface and DH+ Auto Polarity Detection and DH+ Auto Baud Rate Detection.

$1,295 USD List.

you can check https://theautomationblog.com/data-highway-plus-to-ethernet/ for more detailed info.

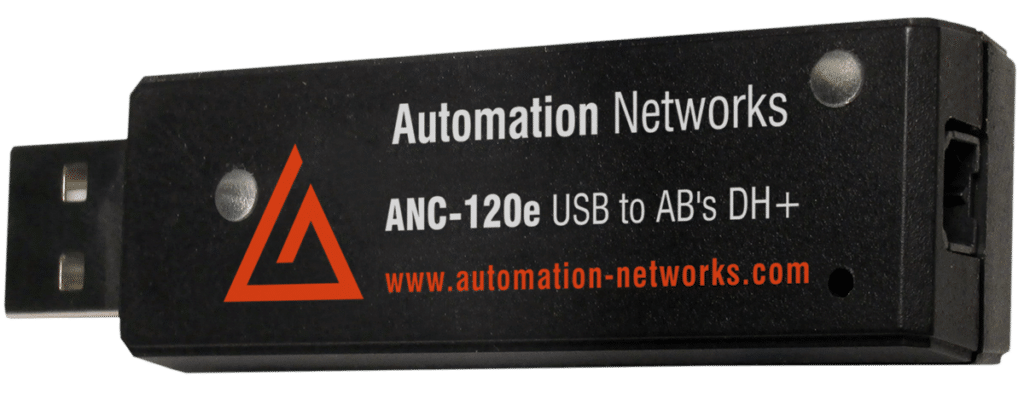

The ANC-120e is a competitive alternative to AB’s 1784-U2DHP PLC Programming Cable

Is an economical and high performance USB-to-Allen-Bradley Data Highway Plus converter interfacing major HMI, SCADA, PLC Programming packages to Devices on DH+. Its features significantly outperform AB’s 1784-U2DHP PLC Programming Cable operating at 12 Mg USB speed with the Controllogix Ethernet/IP Driver.

The ANC-120e works with all SCADA, MMI, PLC programming packages installed on your PC with USB direct access to the DH+ network and stations. These packages include RSLINX/LOGIX Classic & Enterprise with RSLOGIX 5/500, Wonderware DAServer & TCP/IO Server, Citect, and Kepware using Controllogix Ethernet/IP Drivers.

$1,295 USD List.

You can check http://theautomationblog.com/usb-to-data-highway-plus-using-the-anc-120e-a-lower-cost-alternative-to-the-1784-u2dhp/ for more detailed info.

ANC-100e Ethernet IP to AB's DH+ Converter

The Automation Networks ANC-100e communicates with all SCADA, HMI, PLC programming with direct Ethernet/IP access to the DH+ network and stations.

ANC-100e has similar replacement features as the Controllogix 1756-DHRIO / 1756-ENBT, and AB 1784 Interface Cards: 1784-U2DHP, 1784-KTx, 1784-PKTx, 1784-PCMK and Prosoft AN-X2-DHRIO Converters.

$1,295 USD List. Apr 1, 2024

ANC-120e USB to AB's DH+

The ANC-120e works with all SCADA, MMI, PLC programming packages installed on your PC with USB direct access to the DH+ network and stations. These packages include RSLINX/LOGIX Classic & Enterprise with RSLOGIX 5/500, Wonderware DAServer & TCP/IO Server, Citect, and Kepware using Controllogix Ethernet/IP Drivers.