EtherCAT

Ethernet for Control Automation Technology is an Ethernet-based fieldbus system, created by Beckhoff Automation. The protocol is based in IEC 61158 and is suitable for both hard and soft real time requirements in automation technology.

The objective of EtherCAT was to apply Ethernet for automation applications requiring short data overhaul times and diminished equipment costs.

The EtherCAT slave devices read the data addressed to them while the telegram goes through the device, preparing data “on the fly”. Thus, enter data are embedded while the telegram goes through. A frame is not totally recieved before being prepared; instead handling begins as quickly as posible. Sending additionally is led with a base delay of little times.

The EtherCAT protocol is upgraded for process data and is transported diractly inside of the standard IEEE 802.3 Ethernet frame usingEthertype 0x88a4. It might consist of sub-telegrams, every serving a specific memory range of the logical process images that can be up to 4 gigabytes in size. The data succession is autonomous of the physical request of the nods in the network; addresing can be in any order. Broadcast, multicast and correspondence between slaves is conceivable, but need to be started by the master device. In the event that IP routing is required, the EtherCAT protocol can be embedded into UDP/IP datagrams. This also allows any control with Ethernet protocol stack to address EtherCAT systems.

Short process times can be accomplished sice the host microprocessors in the slave devices are not included in the handling of the Ethernet packets to exchange the procedure images. All process data communication is handled in the slave controller hardware. Combined with the functional principle this makes EtherCAT a superior disseminated I/O system: Process data trade with 1000 distributed digital I/O takes around 30 µs, which is ordinary for an transfer of 125 byte over 100Mbit/s Ethernet. Data for and from 100 servoaxis can be updated with up to 10 kHz. Ordinary network update rates are 1–30 kHz, however EtherCAT can be utilized with slower process durations, as well, if the DMA load is too high on yourPC.

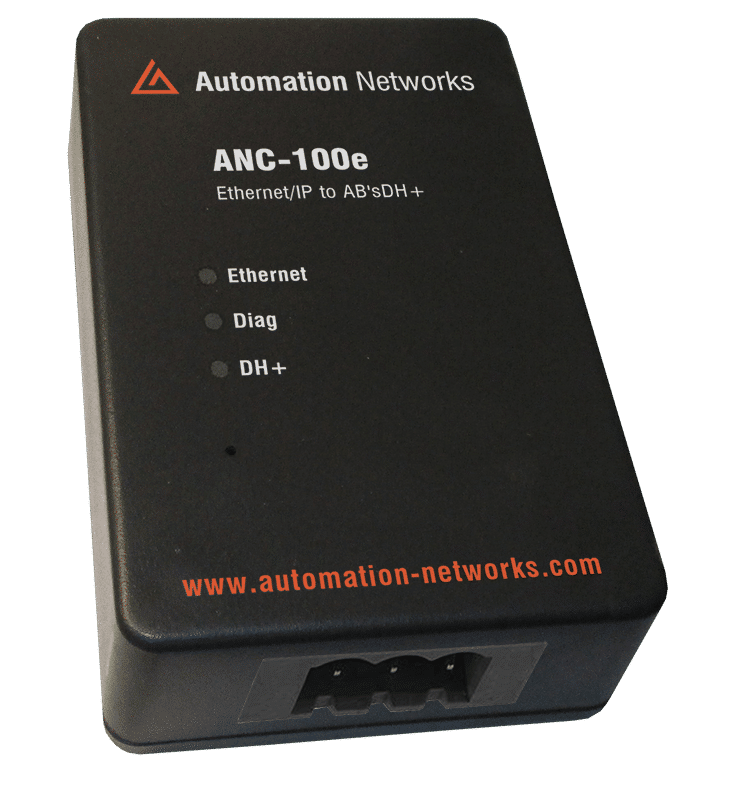

The ANC-100e DH+ converters provide communications between newer Ethernet Technologies and DH+ legacy PLC-5s and SLC/504s

The ANC-100e is a pocket-sized, high performance, Industrial Rated Ethernet DH+ Converter. Features include: Ease of Configuration via Web Interface and DH+ Auto Polarity Detection and DH+ Auto Baud Rate Detection.

$1,295 USD List.

20 min. theautomationblog review.

Data Highway Plus to Ethernet (S02)

In today’s episode of The Automation Show, I unbox and setup an ANC-100E Data Highway Plus to Ethernet bridge from Automation Networks. For more information about the show (and how you could win an ANC-100E) check out the “Show Notes” located below the video. The Automation Show, Episode 2 Show Notes: NOTE: Would you like your … Continue readingData Highway Plus to Ethernet (S02)

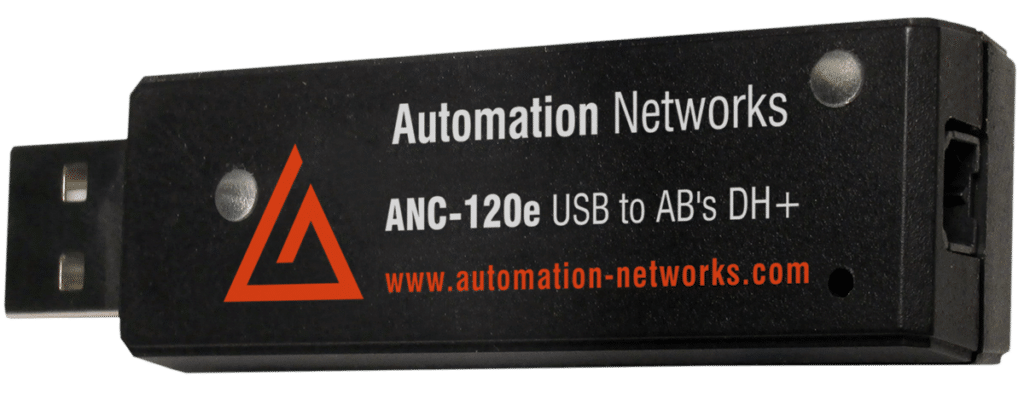

The ANC-120e is a competitive alternative to AB’s 1784-U2DHP PLC Programming Cable

Is an economical and high performance USB-to-Allen-Bradley Data Highway Plus converter interfacing major HMI, SCADA, PLC Programming packages to Devices on DH+. Its features significantly outperform AB’s 1784-U2DHP PLC Programming Cable operating at 12 Mg USB speed with the Controllogix Ethernet/IP Driver.

The ANC-120e works with all SCADA, MMI, PLC programming packages installed on your PC with USB direct access to the DH+ network and stations. These packages include RSLINX/LOGIX Classic & Enterprise with RSLOGIX 5/500, Wonderware DAServer & TCP/IO Server, Citect, and Kepware using Controllogix Ethernet/IP Drivers.

$1,295 USD List.

20 min. theautomationblog review

http://theautomationblog.com/usb-to-data-highway-plus-using-the-anc-120e-a-lower-cost-alternative-to-the-1784-u2dhp/ for more detailed info.

ANC-100e Ethernet IP to AB's DH+ Converter

The Automation Networks ANC-100e communicates with all SCADA, HMI, PLC programming with direct Ethernet/IP access to the DH+ network and stations.

ANC-100e has similar replacement features as the Controllogix 1756-DHRIO / 1756-ENBT, and AB 1784 Interface Cards: 1784-U2DHP, 1784-KTx, 1784-PKTx, 1784-PCMK and Prosoft AN-X2-DHRIO Converters.

$1,295 USD List. Apr 1, 2024

ANC-120e USB to AB's DH+

The ANC-120e works with all SCADA, MMI, PLC programming packages installed on your PC with USB direct access to the DH+ network and stations. These packages include RSLINX/LOGIX Classic & Enterprise with RSLOGIX 5/500, Wonderware DAServer & TCP/IO Server, Citect, and Kepware using Controllogix Ethernet/IP Drivers.