Guardlogix Controllers

Allen-Bradley GuardLogix controllers are a family of programmable logic controllers (PLCs) that are engineered to provide advanced safety and automation capabilities in a single integrated platform. These controllers are part of the ControlLogix family and are designed to meet the requirements of safety-critical applications, where human lives and equipment integrity are at stake.

Key Features of GuardLogix Controllers

Safety Functions: The primary feature that sets GuardLogix controllers apart from standard PLCs is their comprehensive support for safety functions. They are capable of executing safety-related tasks in compliance with industry standards such as ISO 13849 and IEC 62061. This includes monitoring safety devices, ensuring safe machine states, and executing emergency shutdowns when necessary.

Integrated Safety: GuardLogix controllers integrate safety functionality with standard control capabilities in a single controller. This means that safety and standard control functions coexist within the same hardware platform, reducing the complexity of the control system and simplifying design and maintenance.

Safety Certification: GuardLogix controllers are certified to various international safety standards, including SIL 3 (Safety Integrity Level 3) and PL e (Performance Level e). These certifications ensure that the controllers can reliably perform safety-related tasks, making them suitable for high-risk applications.

Diagnostics and Monitoring: GuardLogix controllers offer advanced diagnostics and monitoring features for safety-related components. This allows operators and maintenance personnel to detect faults or malfunctions in safety devices, enabling timely corrective actions to be taken.

Redundancy Options: In mission-critical applications where system uptime is essential, GuardLogix controllers support redundancy configurations. Redundancy ensures that if one controller or channel fails, another takes over seamlessly, minimizing downtime and maintaining safety.

Flexibility and Scalability: These controllers are part of the ControlLogix platform, known for its scalability and flexibility. Users can choose from a range of controller models to match the complexity of their application. Additionally, GuardLogix controllers can be easily integrated with other ControlLogix modules and accessories.

Programming and Configuration: GuardLogix controllers are programmed using Rockwell Automation’s Studio 5000 software, which provides a user-friendly environment for developing safety and standard control logic. The software includes features such as safety instructions and function blocks specifically designed for safety programming.

Industrial Applications:

Allen-Bradley GuardLogix controllers are of paramount significance in various industrial applications, particularly in those where safety is a primary concern. Here are some key reasons why these controllers are vital:

Worker Safety: In manufacturing and industrial environments, the safety of workers is paramount. GuardLogix controllers play a crucial role in ensuring that machines and processes operate safely, minimizing the risk of accidents and injuries.

Compliance with Regulations: Industries are subject to strict safety regulations and standards. GuardLogix controllers provide a platform for achieving compliance with these standards, helping organizations avoid fines and legal liabilities.

Reduced Downtime: Safety-related incidents can result in costly downtime. By quickly detecting and responding to safety hazards, GuardLogix controllers help minimize unplanned downtime and production losses.

Risk Reduction: GuardLogix controllers help reduce the risk associated with complex machinery and processes. Their ability to execute emergency shutdowns and safety interlocks ensures that potentially hazardous situations are mitigated.

Integration with Control Systems: These controllers seamlessly integrate safety functions with standard control functions. This integration streamlines the design, configuration, and maintenance of industrial control systems, reducing complexity and improving efficiency.

Increased Productivity: When safety is ensured, operators and maintenance personnel can focus on optimizing processes and increasing productivity rather than worrying about safety hazards.

Versatility: GuardLogix controllers are versatile and can be used in a wide range of applications, including robotics, material handling, packaging, and more. Their adaptability makes them suitable for various industries and scenarios.

Future-Proofing: As industries evolve and adopt new technologies, GuardLogix controllers can evolve with them. They are designed to accommodate changes and upgrades, ensuring that safety and control systems remain effective and up-to-date.

Allen-Bradley GuardLogix controllers are a critical component of industrial safety and automation systems. Their ability to integrate safety functions with standard control, their adherence to safety standards, and their role in minimizing risks and ensuring worker safety make them indispensable in various industries. By providing a comprehensive safety solution within a single platform, GuardLogix controllers contribute to the efficiency, productivity, and compliance of industrial processes. As industries continue to prioritize safety and automation, the significance of GuardLogix controllers in safeguarding both humans and machines remains paramount.

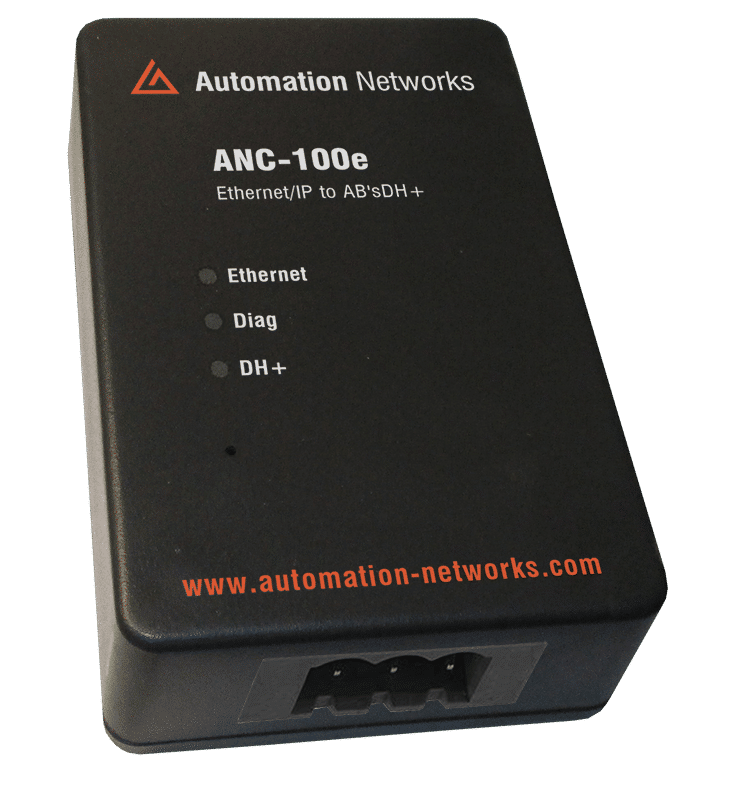

The ANC-100e DH+ converters provide communications between newer Ethernet Technologies and DH+ legacy PLC-5s and SLC/504s

The ANC-100e is a pocket-sized, high performance, Industrial Rated Ethernet DH+ Converter. Features include: Ease of Configuration via Web Interface and DH+ Auto Polarity Detection and DH+ Auto Baud Rate Detection.

$1,295 USD List.

20 min. theautomationblog review.

Data Highway Plus to Ethernet (S02)

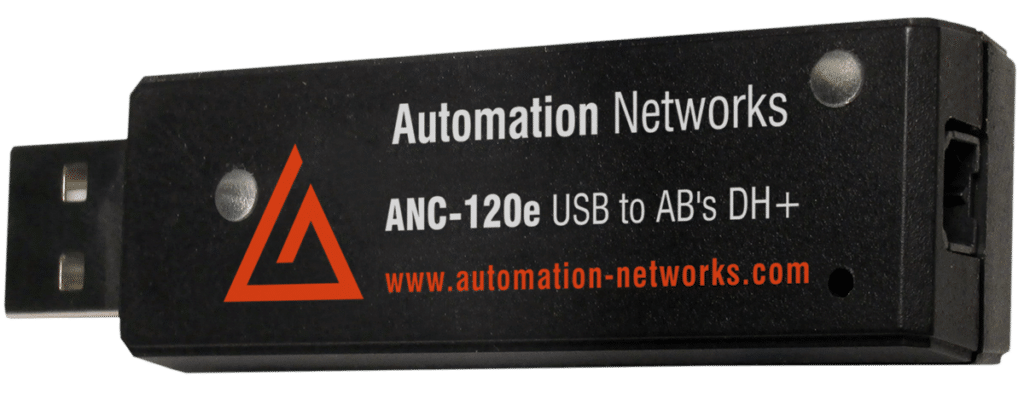

The ANC-120e is a competitive alternative to AB’s 1784-U2DHP PLC Programming Cable

Is an economical and high performance USB-to-Allen-Bradley Data Highway Plus converter interfacing major HMI, SCADA, PLC Programming packages to Devices on DH+. Its features significantly outperform AB’s 1784-U2DHP PLC Programming Cable operating at 12 Mg USB speed with the Controllogix Ethernet/IP Driver.

The ANC-120e works with all SCADA, MMI, PLC programming packages installed on your PC with USB direct access to the DH+ network and stations. These packages include RSLINX/LOGIX Classic & Enterprise with RSLOGIX 5/500, Wonderware DAServer & TCP/IO Server, Citect, and Kepware using Controllogix Ethernet/IP Drivers.

$1,295 USD List.

20 min. theautomationblog review

http://theautomationblog.com/usb-to-data-highway-plus-using-the-anc-120e-a-lower-cost-alternative-to-the-1784-u2dhp/ for more detailed info.

ANC-100e Ethernet IP to AB's DH+ Converter

The Automation Networks ANC-100e communicates with all SCADA, HMI, PLC programming with direct Ethernet/IP access to the DH+ network and stations.

ANC-100e has similar replacement features as the Controllogix 1756-DHRIO / 1756-ENBT, and AB 1784 Interface Cards: 1784-U2DHP, 1784-KTx, 1784-PKTx, 1784-PCMK and Prosoft AN-X2-DHRIO Converters.

$1,295 USD List. Apr 1, 2024

ANC-120e USB to AB's DH+

The ANC-120e works with all SCADA, MMI, PLC programming packages installed on your PC with USB direct access to the DH+ network and stations. These packages include RSLINX/LOGIX Classic & Enterprise with RSLOGIX 5/500, Wonderware DAServer & TCP/IO Server, Citect, and Kepware using Controllogix Ethernet/IP Drivers.