Data Highway Plus Protocol

The Allen-Bradley Data Highway Plus (DH+), developed by Rockwell Automation, is a key communication network for industrial automation. Originating in the 1980s, DH+ improved upon its predecessor, Data Highway, becoming popular in industrial settings.

Early Days:

Rockwell Automation introduced Data Highway in the 1980s, marking a revolution in industrial communication. This system let devices like programmable logic controllers (PLCs) interact efficiently. But as demands grew, so did the need for a more advanced system. Enter Data Highway Plus.

Key Features:

-

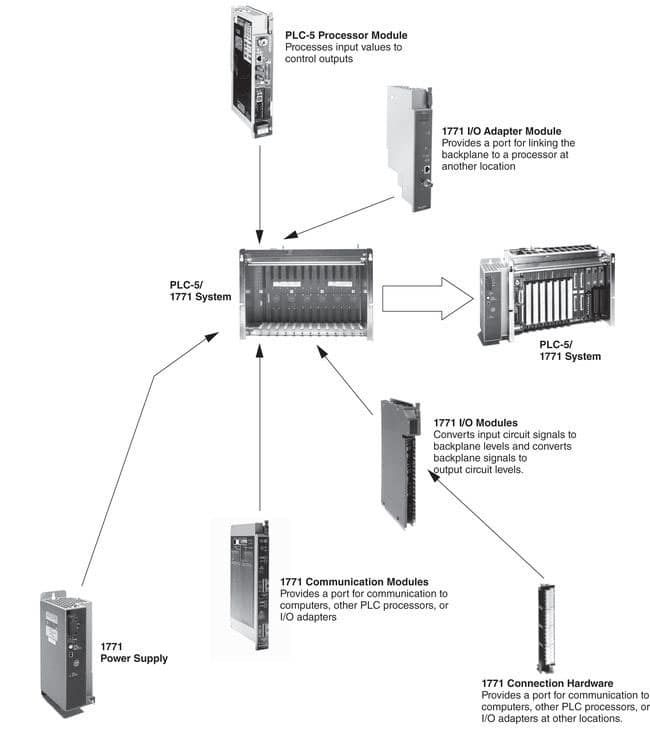

PLCs and Devices: DH+ networks connect PLCs, motor controllers, and human-machine interfaces. These devices use DH+ modules for communication.

-

Software Tools: Engineers use Rockwell Automation software, like RSLogix 5 or RSLogix 5000, to configure DH+ networks.

-

Communication Protocol: DH+ uses a special protocol to manage data transmission across the network.

-

Physical Layer: The network often relies on RS-485 serial interfaces, sometimes using coaxial cables in older setups.

-

Hardware Components: Essential items like communication cards and connectors form the backbone of a DH+ network.

Operation Simplified:

-

Configuring Devices: Each device gets a unique node address for identification.

-

Making Connections: Devices link up using cables and connectors in a linear or multidrop layout.

-

Setting Parameters: The network software sets communication details like baud rate and parity.

-

Exchanging Data: Configured devices can now share data and control commands, vital for automated processes.

-

Polling and Scanning: A master device coordinates communication, ensuring efficient data handling.

-

Real-Time Control: DH+ excels in scenarios needing timely responses, like manufacturing.

Advantages:

- Interoperability: DH+ ensures Allen-Bradley devices work seamlessly together.

- Reliability: Known for its robust performance, DH+ suits mission-critical tasks.

- Predictable Timing: It offers consistent communication, key for real-time operations.

- Legacy Integration: Older systems can easily join modern setups, thanks to backward compatibility.

- Ease of Use: The network’s setup and management are user-friendly.

Aplications:

- Manufacturing: DH+ orchestrates machinery and production lines.

- Process Control: It’s crucial in chemical, pharmaceutical, and petrochemical industries.

- Utilities: DH+ helps in managing power distribution and electrical substations.

- Building Automation: It plays a role in managing HVAC systems and lighting.

- Water Treatment: Vital in automating water and wastewater processes.

- Material Handling: DH+ controls systems like conveyor belts in logistics centers.

Our Products

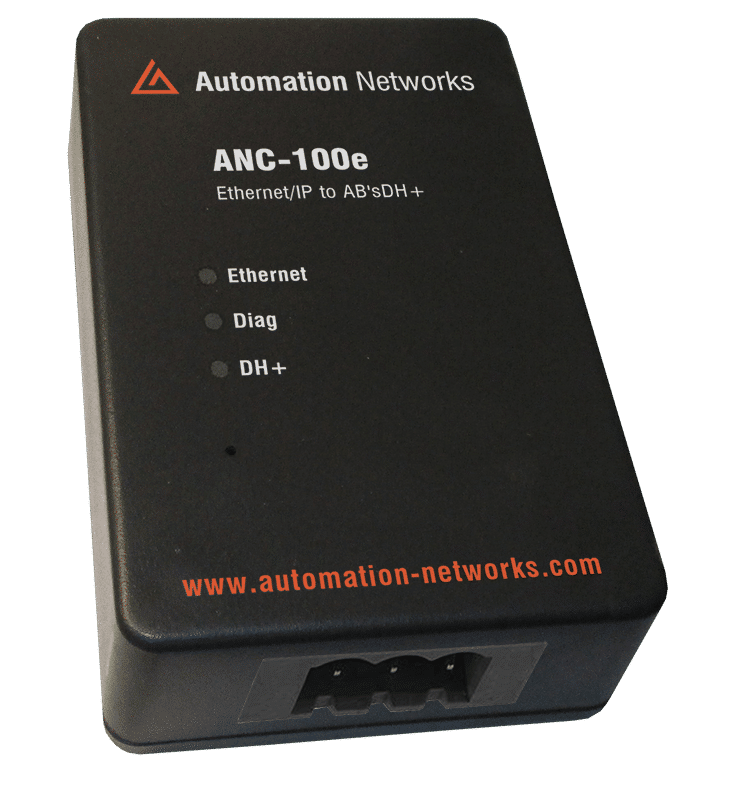

The ANC-100e DH+ converters provide communications between newer Ethernet Technologies and DH+ legacy PLC-5s and SLC/504s

The ANC-100e is a pocket-sized, high performance, Industrial Rated Ethernet DH+ Converter. Features include: Ease of Configuration via Web Interface and DH+ Auto Polarity Detection and DH+ Auto Baud Rate Detection.

$1,295 USD List.

Data Highway Plus to Ethernet (S02)

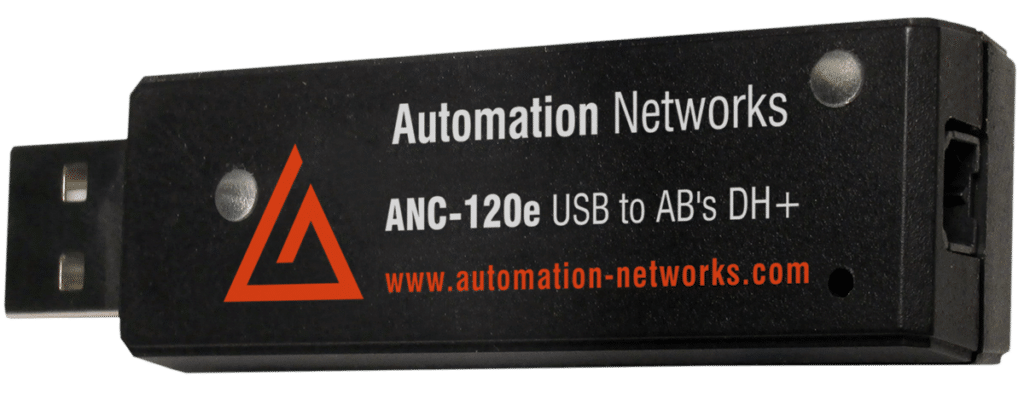

The ANC-120e is a competitive alternative to AB’s 1784-U2DHP PLC Programming Cable

Is an economical and high performance USB-to-Allen-Bradley Data Highway Plus converter interfacing major HMI, SCADA, PLC Programming packages to Devices on DH+. Its features significantly outperform AB’s 1784-U2DHP PLC Programming Cable operating at 12 Mg USB speed with the Controllogix Ethernet/IP Driver.

The ANC-120e works with all SCADA, MMI, PLC programming packages installed on your PC with USB direct access to the DH+ network and stations. These packages include RSLINX/LOGIX Classic & Enterprise with RSLOGIX 5/500, Wonderware DAServer & TCP/IO Server, Citect, and Kepware using Controllogix Ethernet/IP Drivers.

$1,295 USD List.

USB To Data Highway Plus (DHP, DH+) – Using the ANC-120e, a lower cost alternative to the 1784-U2DHP