Interfacing Ignition HMI with Legacy Allen-Bradley Controllers Using ANC-100e and ANC-120e

Introduction: The Legacy Challenge in Modern Plants

Industrial automation plants are rarely built from scratch. Instead, they evolve layer by layer over decades. A production line might have machinery dating back to the 1990s, with controllers that are still as reliable today as they were on the day of commissioning. The Allen-Bradley SLC 5/04 and PLC-5 families are perfect examples: rugged, proven controllers that remain in service worldwide, especially in manufacturing, utilities, food processing, and energy.

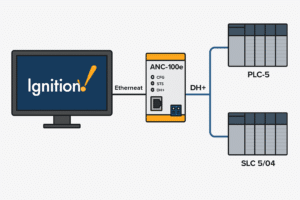

The problem, however, is that these controllers communicate over a protocol called Data Highway Plus (DH+). This was cutting-edge when it was introduced, but modern SCADA and HMI platforms—like Ignition by Inductive Automation—speak a different language. Ignition thrives on Ethernet/IP, OPC UA, and other modern network standards. Connecting Ignition to legacy controllers on DH+ requires a translator, and without one, valuable process data risks being locked away in an isolated island of legacy infrastructure.

Automation Networks provides exactly this bridge with two devices: the ANC-100e and the ANC-120e. Together, they extend the life of legacy Allen-Bradley controllers, enabling them to participate fully in modern SCADA systems. The ANC-100e is an Ethernet-to-DH+ gateway designed for permanent plant installations. The ANC-120e is a USB-to-DH+ converter—an ideal tool for engineers in the field, and the modern alternative to the once-ubiquitous Rockwell 1784-U2DHP cable.

Why Bridging Matters for Ignition and Allen-Bradley Controllers

The need to integrate Ignition with legacy controllers is not simply a matter of convenience; it is essential for digital transformation. Companies cannot afford to rip out reliable controllers that still perform critical tasks. At the same time, plant managers cannot ignore the need for modern data collection, visualization, and enterprise-level connectivity.

DH+ was never designed for enterprise IT systems. It was intended for controller-to-controller communication and local HMI panels, not cloud historians or plant-wide analytics. This creates a gap: critical process data exists, but without the right gateway, it is invisible to Ignition.

Ignition: Modern SCADA That Brings Legacy Systems Into the Future

Ignition by Inductive Automation has become one of the most widely adopted SCADA and HMI platforms in the world. It is known for its flexibility, scalability, and licensing model, which allow plants of any size to deploy powerful visualization and data management tools without the limitations of traditional SCADA software. More importantly, Ignition is designed not just for modern systems but also for plants that need to connect to legacy controllers and networks. This ability to bridge old and new is one of the platform’s greatest strengths.

What Ignition Does

At its core, Ignition is a universal industrial software platform that combines HMI, SCADA, MES, and IIoT functionality into one package. It allows operators to monitor processes in real time, historians to log data for long-term analysis, and management teams to view dashboards that summarize plant performance. It is built on open technologies like Java, SQL, and OPC UA, making it highly adaptable to different industries and hardware environments.

Unlike older SCADA systems that charge per client or per tag, Ignition offers unlimited clients, tags, and connections under a single license. This model makes it possible for companies to scale from a single-machine interface to an enterprise-wide SCADA system without worrying about escalating costs. Its modular architecture also allows organizations to choose the exact functionality they need, whether that’s alarming, reporting, or enterprise-level analytics.

Bridging Ethernet with Legacy Controllers

While Ignition is built for Ethernet/IP and OPC UA, most plants still rely on legacy controllers. Systems such as Allen-Bradley PLC-5 and SLC 5/04 are widely deployed and continue to run critical processes, but they communicate using Data Highway Plus (DH+), a protocol that predates Ethernet. Without help, Ignition cannot talk directly to these controllers.

That’s where bridging devices like the ANC-100e and ANC-120e come into play. They serve as translators between Ignition’s Ethernet-based communication and the legacy DH+ networks still found in factories. The ANC-100e, an Ethernet-to-DH+ gateway, allows Ignition to connect permanently to legacy controllers through the standard RSLinx ControlLogix Ethernet driver. The ANC-120e, a USB-to-DH+ converter, gives engineers a portable solution for connecting laptops directly to older PLCs.

By inserting one of these gateways into the network, Ignition can browse, read, and write tags on PLC-5 and SLC 5/04 controllers as though they were native Ethernet devices. This simple addition unlocks valuable data, making legacy controllers visible in Ignition’s dashboards, alarms, and reports. Plants can continue using their proven hardware while gaining the benefits of a modern SCADA platform.

The Value of Bridging

For many plants, replacing legacy controllers is not an option. They are reliable, embedded in critical processes, and costly to replace. At the same time, ignoring them means leaving valuable operational data siloed. Ignition’s openness, combined with bridging solutions like the ANC gateways, ensures that no device is left behind. Legacy controllers can participate in digital transformation, enabling real-time visualization, enterprise integration, and analytics without expensive migrations.

In short, Ignition is not only a SCADA system for modern Ethernet-based plants. It is also the platform that makes it possible to bring decades-old equipment into the future, creating a unified environment where both legacy and modern systems coexist seamlessly.

The ANC-100e: Ethernet to DH+ Made Simple

The ANC-100e is built for permanent deployment in the control cabinet. It sits on a DIN rail like any other piece of industrial networking equipment and provides a standard Ethernet connection to Ignition. On its other side, it connects to the DH+ network that ties together legacy Allen-Bradley controllers.

Once installed, the ANC-100e becomes a transparent bridge. Ignition can connect through it using the built-in drivers for SLC and PLC-5, entering the device’s IP address and a simple connection path. From that moment, the DH+ network behaves as though it were just another set of Ethernet devices on the plant floor.

What makes the ANC-100e especially valuable is its reliability. Plants rely on continuous uptime, and this gateway is designed for 24/7 operation. It eliminates the need for outdated PCI cards or proprietary interfaces that tie engineers to legacy PCs. Instead, everything happens over Ethernet, making it easy to integrate into existing networks. For SCADA projects that require ongoing visibility into legacy controllers, the ANC-100e is the right choice.

The ANC-100e is a full-function Ethernet-to-DH+ converter, built for seamless integration with all major PLC programming, HMI, and SCADA packages. It supports every version of RSLinx Classic as well as the latest RSLinx Enterprise, making it the perfect bridge between modern software and legacy Allen-Bradley controllers.

Setup is straightforward: the ANC-100e uses the standard ControlLogix Ethernet driver in RSLinx, providing a fast, reliable Ethernet/IP link. With it, PanelView Plus 6 and 7 terminals can message over Ethernet/IP to multiple SLC 5/04 and PLC-5 controllers on DH+, eliminating the need for outdated interface hardware.

Priced economically at $1,195 USD (list), the ANC-100e is not only a modern substitute for discontinued Rockwell interface cards—including the 1784-U2DHP, 1784-KTx, 1784-PKTx, and 1784-PCMK—it also serves as an alternative to the ProSoft AN-X2-AB-DHRIO and AN-X4-AB-DHRIO gateways. This makes it a cost-effective and versatile choice for plants looking to maintain connectivity without overspending.

The device supports all standard DH+ baud rates—57.6, 115.2, and 230.4 Kbaud—while handling long cable runs with reliability. Intelligent features like auto-baud and auto-polarity detection simplify installation and speed up deployment.

Compact and versatile, the ANC-100e is available in both pocket-sized desktop form and DIN-rail mounting options. For easy DH+ wiring, it provides a 3-pin Phoenix blue hose connector and includes an 8-pin mini-DIN cable for direct connection to PLC ports.

The ANC-120e: A Modern Alternative to the 1784-U2DHP

For engineers and technicians who need to connect directly to a DH+ network from a laptop, the ANC-120e is the tool of choice. It is a USB-to-DH+ converter that installs quickly, travels easily, and provides the same functionality once offered by Rockwell’s famous 1784-U2DHP cable.

The ANC-120e solves this problem elegantly. It is designed for current Windows environments, supports both RSLinx and Ignition, and delivers faster, more stable communication than the legacy Rockwell cable. In other words, it is not only a replacement for the 1784-U2DHP—it is an improvement. Engineers no longer need to rely on legacy drivers or outdated machines. With the ANC-120e, they can plug into DH+ using the laptops they already use every day.

For field service, commissioning, or maintenance teams, the ANC-120e is indispensable. It enables fast troubleshooting, temporary SCADA connections, and support for legacy installations around the world. OEMs can standardize on it as their field tool, ensuring they always have access to DH+ networks without hunting for discontinued parts.

Performance is another key advantage. Operating over USB 2.0 at 12 Mb, the ANC-120e delivers stable and high-speed communications with DH+ devices at rates up to 230.4 Kb. Its intelligent design includes auto-baud and auto-polarity detection, minimizing setup time and eliminating common configuration errors.

More than just a replacement for the 1784-U2DHP, the ANC-120e is a superior option: affordable, portable, rugged, and fully supported. With a price of $995.00, it provides outstanding value for engineers, OEMs, and maintenance teams who need dependable access to legacy Allen-Bradley systems.

In short, the ANC-120e doesn’t just replicate the 1784-U2DHP—it improves upon it. By offering modern OS support, faster performance, lower cost, and ongoing availability, the ANC-120e ensures engineers have a dependable, future-proof tool for accessing DH+ networks well into the future.

Practical Integration with Ignition: A Narrative Walkthrough

Configuring Ignition to work with the ANC-100e or ANC-120e is straightforward. The process begins with ensuring the ANC device is connected—either by plugging the USB converter into a laptop or placing the Ethernet gateway onto the plant network. Once the driver for the ANC-120e is installed, or the IP address of the ANC-100e is confirmed, the rest of the configuration happens entirely in Ignition.

Inside the Ignition Gateway, the engineer navigates to the OPC UA device section and chooses to add a new device. From the list of available drivers, the appropriate choice is Allen-Bradley SLC or PLC-5. The engineer then enters a name for the connection, the IP address of the ANC device, and a connection path that points Ignition to the correct DH+ node. For example, if the target SLC 5/04 has a DH+ address of 03, the path is entered as 1,1,2,3.

Once saved, Ignition attempts to connect. Within moments, the status shows “Connected,” and the engineer can browse the DH+ device through Ignition’s Quick Client. Expanding the device reveals its tags, and selecting any tag allows the engineer to read its current value in real time. At that moment, a controller that predates modern Ethernet standards is fully visible inside Ignition, ready for dashboards, alarms, and historians.

Real-World Scenarios and Success Stories

Consider a food processing plant that has relied on a network of SLC 5/04 controllers for decades. The equipment is still reliable, but the company recently adopted Ignition to standardize visualization and reporting across its global sites. Without a bridge, the SLC 5/04 controllers would remain invisible to the new system, leaving critical production data stranded. By deploying ANC-100e gateways, the plant integrates these controllers seamlessly, giving operators real-time visibility into throughput, quality, and downtime.

In another case, a utilities provider with multiple water treatment sites relies on a mix of PLC-5s and newer controllers. Maintenance teams often travel between sites, carrying laptops that need to connect quickly to DH+ networks for diagnostics. By standardizing on the ANC-120e, the teams have a reliable, modern tool that replaces the discontinued 1784-U2DHP and works across all their locations. The ability to connect using standard laptops without relying on legacy hardware saves time, reduces costs, and ensures support continuity.

OEMs also benefit. A machine builder that delivered PLC-5-based equipment years ago can still support those installations globally using the ANC-120e. Instead of stocking old Rockwell cables, their engineers carry a single device that works with both RSLinx and Ignition, giving them the flexibility to troubleshoot, update, or integrate systems on-site.

Troubleshooting, Best Practices, and Peace of Mind

When connecting legacy controllers to modern SCADA platforms, reliability and support are paramount. The ANC-100e and ANC-120e are designed with these realities in mind. The Ethernet gateway is built for continuous operation in demanding environments, while the USB converter is rugged enough to travel in a field engineer’s toolkit.

Best practices include confirming the correct DH+ node addresses, verifying driver installation for the ANC-120e, and ensuring that Ignition’s OPC UA configuration points to the correct device path. Once these details are in place, communication is consistent and dependable.

For plants concerned with security, the ANC devices integrate smoothly into existing IT policies. The Ethernet gateway can be assigned an IP address within standard firewall rules, while the USB converter maintains control by limiting access to authorized laptops. This balance of accessibility and security ensures that legacy data can be unlocked without introducing unnecessary risks.

About Automation Networks

Automation Networks is dedicated to bridging the gap between legacy systems and modern industrial platforms. With products trusted by manufacturers, utilities, and OEMs worldwide, the company focuses on practical solutions that extend the life of existing assets. The ANC-100e and ANC-120e exemplify this approach: simple, reliable, and effective tools that make legacy controllers visible in today’s SCADA and IIoT environments.

The company’s philosophy is straightforward: legacy does not mean obsolete. By providing cost-effective gateways, Automation Networks helps customers avoid unnecessary replacements, protect their investments, and move forward with digital transformation at their own pace.

Bridging Legacy with the Future

The industrial world is built on decades of investment in automation hardware. Replacing every legacy controller is neither feasible nor necessary. What matters is ensuring those controllers remain connected, visible, and valuable in a modern SCADA environment.

Ignition HMI is one of the most powerful platforms available today, but without the right gateway, it cannot communicate with Allen-Bradley SLC 5/04 or PLC-5 controllers on DH+. The ANC-100e and ANC-120e provide that bridge. The ANC-100e delivers permanent, Ethernet-based access for plant-wide SCADA systems. The ANC-120e offers a portable, modern alternative to the discontinued 1784-U2DHP cable, giving engineers and technicians a reliable tool for direct access.

Together, these devices ensure that legacy controllers are not left behind. They keep proven equipment in service, unlock valuable process data, and make it possible for plants to embrace the future without abandoning the past.