Melsecnet

MELSECNET is a network communication protocol and system used primarily in industrial automation and control systems. This brief overview of MELSECNET will include its history, key components, operation, benefits, applications, and future prospects.

History:

MELSECNET is a product of Mitsubishi Electric, a prominent Japanese multinational corporation known for its contributions to the field of industrial automation. Mitsubishi Electric introduced the MELSEC series in the 1970s, which included programmable logic controllers (PLCs), human-machine interfaces (HMIs), and various other automation components. As industrial automation grew in complexity, the need for reliable and efficient communication between these components became evident, leading to the development of MELSECNET.

Key Components:

MELSECNET consists of several key components and concepts:

PLCs (Programmable Logic Controllers): These are the central control units in industrial automation systems. Mitsubishi Electric’s PLCs, often part of the MELSEC series, play a crucial role in the implementation of MELSECNET.

Network Modules: MELSECNET utilizes specialized communication modules that can be installed in the PLCs or other devices. These modules enable communication over the MELSECNET network.

Master-Slave Architecture: MELSECNET follows a master-slave architecture, where one PLC (the master) controls and communicates with several other PLCs or devices (the slaves). This structure allows for centralized control and efficient data exchange.

MELSEC Protocol: MELSECNET relies on its proprietary communication protocol for data exchange. This protocol ensures data integrity, reliability, and speed within the network.

Operation:

MELSECNET operates by establishing communication links between various devices within an industrial automation system. Here’s how it works:

Configuration: First, the network modules are physically installed in the PLCs or devices that need to communicate with each other. Each module is configured with specific network parameters.

Master Configuration: In a MELSECNET network, one PLC is designated as the master, responsible for initiating and managing communication. The master PLC is programmed to send requests and commands to the slave devices.

Slave Configuration: Other PLCs or devices are configured as slaves. They await instructions from the master and respond accordingly. The slave devices can also send data back to the master when requested.

Data Exchange: The master PLC sends requests for data or control commands to the slave devices. The slaves process these requests and send back the required data or execute the specified actions.

Response and Acknowledgment: The communication protocol ensures that data is transmitted accurately and reliably. Acknowledgment messages confirm successful data transfer, and error handling mechanisms are in place to address any issues that may arise.

Real-Time Operation: MELSECNET is designed for real-time operation, making it suitable for time-sensitive industrial processes. It provides deterministic communication, ensuring that data arrives within predictable timeframes.

Benefits:

MELSECNET offers several advantages in industrial automation applications:

Reliability: The proprietary MELSEC protocol is known for its reliability and robustness, making it suitable for mission-critical processes.

Deterministic Communication: MELSECNET ensures predictable and consistent data exchange, crucial in applications where timing is critical.

Scalability: The network can be easily expanded by adding more devices or modules, accommodating the growth of an automation system.

Integration: MELSECNET is well-integrated with Mitsubishi Electric’s PLCs and automation equipment, simplifying system design and implementation.

High-Speed Data Transfer: It supports high-speed communication, allowing for rapid exchange of data between devices.

Applications:

MELSECNET finds applications in various industrial sectors, including:

Manufacturing: MELSECNET is widely used in manufacturing plants for process control, machinery automation, and production line management.

Energy Management: It plays a crucial role in managing and controlling energy systems, such as power distribution, renewable energy installations, and grid management.

Transportation: MELSECNET is utilized in transportation systems for tasks like controlling automated guided vehicles (AGVs) and traffic management.

Building Automation: In building automation and HVAC (heating, ventilation, and air conditioning) systems, MELSECNET helps maintain comfort and energy efficiency.

Robotics: Industrial robots and robotic assembly lines benefit from MELSECNET’s real-time communication capabilities.

Water and Wastewater Management: It is employed in the control and monitoring of water treatment plants and wastewater facilities.

Future Prospects:

As industrial automation continues to advance, MELSECNET is likely to evolve and adapt to new technologies and industry trends. Some potential future developments include:

Integration with IoT: MELSECNET could incorporate IoT (Internet of Things) capabilities for enhanced data analytics and remote monitoring.

Cybersecurity Enhancements: Given the increasing importance of cybersecurity, MELSECNET may see improvements in security protocols and encryption to protect against cyber threats.

Cloud Integration: Integration with cloud platforms could enable data storage, analysis, and remote access to automation systems.

Compatibility with Emerging Protocols: MELSECNET may evolve to work seamlessly with emerging industrial communication protocols to ensure interoperability in complex systems.

MELSECNET is a robust and reliable network communication protocol essential in industrial automation and control systems. Its history, key components, operation, benefits, applications, and future prospects highlight its significance in facilitating efficient and real-time communication among devices in industrial settings. As technology continues to advance, MELSECNET is likely to remain a vital component in the world of automation.

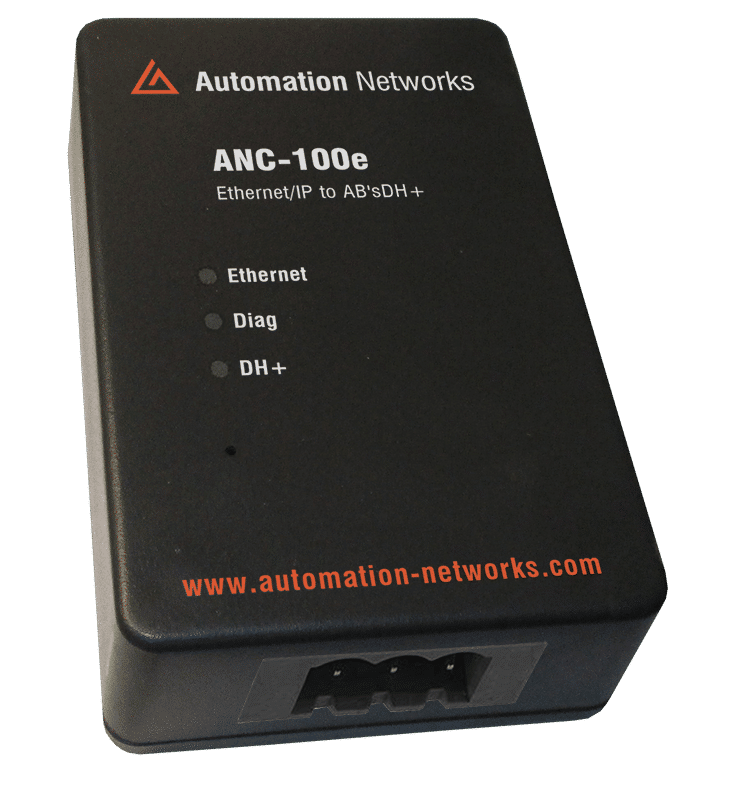

The ANC-100e DH+ converters provide communications between newer Ethernet Technologies and DH+ legacy PLC-5s and SLC/504s

The ANC-100e is a pocket-sized, high performance, Industrial Rated Ethernet DH+ Converter. Features include: Ease of Configuration via Web Interface and DH+ Auto Polarity Detection and DH+ Auto Baud Rate Detection.

$1,295 USD List.

20 min. theautomationblog review.

https://theautomationblog.com/data-highway-plus-to-ethernet/

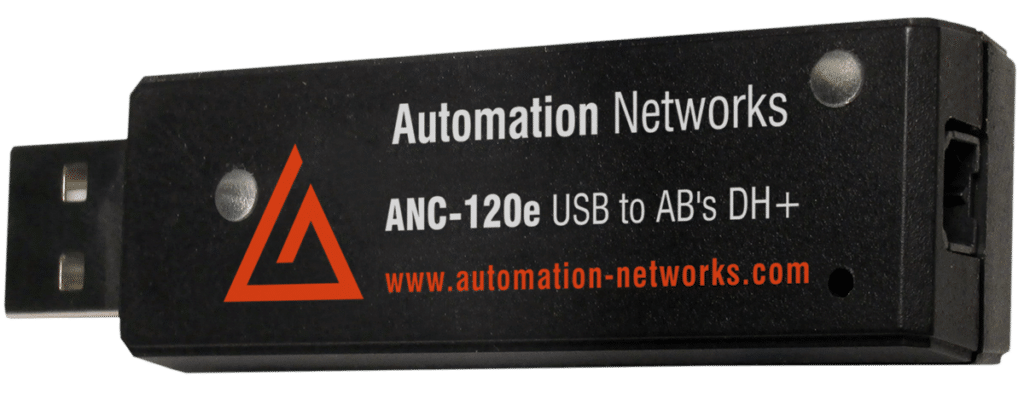

The ANC-120e is a competitive alternative to AB’s 1784-U2DHP PLC Programming Cable

Is an economical and high performance USB-to-Allen-Bradley Data Highway Plus converter interfacing major HMI, SCADA, PLC Programming packages to Devices on DH+. Its features significantly outperform AB’s 1784-U2DHP PLC Programming Cable operating at 12 Mg USB speed with the Controllogix Ethernet/IP Driver.

The ANC-120e works with all SCADA, MMI, PLC programming packages installed on your PC with USB direct access to the DH+ network and stations. These packages include RSLINX/LOGIX Classic & Enterprise with RSLOGIX 5/500, Wonderware DAServer & TCP/IO Server, Citect, and Kepware using Controllogix Ethernet/IP Drivers.

$1,295 USD List.

20 min. theautomationblog review

http://theautomationblog.com/usb-to-data-highway-plus-using-the-anc-120e-a-lower-cost-alternative-to-the-1784-u2dhp/ for more detailed info.

ANC-100e Ethernet IP to AB's DH+ Converter

The Automation Networks ANC-100e communicates with all SCADA, HMI, PLC programming with direct Ethernet/IP access to the DH+ network and stations.

ANC-100e has similar replacement features as the Controllogix 1756-DHRIO / 1756-ENBT, and AB 1784 Interface Cards: 1784-U2DHP, 1784-KTx, 1784-PKTx, 1784-PCMK and Prosoft AN-X2-DHRIO Converters.

$1,295 USD List. Apr 1, 2024

ANC-120e USB to AB's DH+

The ANC-120e works with all SCADA, MMI, PLC programming packages installed on your PC with USB direct access to the DH+ network and stations. These packages include RSLINX/LOGIX Classic & Enterprise with RSLOGIX 5/500, Wonderware DAServer & TCP/IO Server, Citect, and Kepware using Controllogix Ethernet/IP Drivers.